The Basic Principles Of Mobile Sandblasting Near Me

Wiki Article

The Ultimate Guide To Portable Sandblaster

Table of ContentsLittle Known Questions About Sandblaster For Sale.The Ultimate Guide To Sand Blaster Harbor FreightLittle Known Facts About Sandblasting Near Me.The 25-Second Trick For Mobile Sandblasting Near MeGetting The Sandblaster For Sale To WorkSand Blasting Sand Things To Know Before You Buy

Steel nozzles will not damage when dropped. Economic situation and also non-industrial sandblasters for residence or DIY use frequently come with low-priced steel nozzles. Based exclusively on wear resistance boron carbide and binderless WC last approximately seven-time longer than cemented WC. If you bang a boron carbide or silicon nitride nozzle right into a part, grate, or cupboard wall, after that the nozzle is more probable to fracture contrasted to a cement tungsten carbide nozzle.The unpleasant blasting procedure removes the surface area contamination and also converts it into dust. The abrasive blaster can also deeply blast a steel surface to completely remove any rust, range, or adherents to a NACE/SSPC "white metal" cleanliness grade.

Next, the surface is peened with small spheres or microbeads to refine the surface area coating. If the component has a rough (high roughness standard, Ra) surface finish like an as-cast or as-forged surface, then peening can decently improve the surface finish. If the part has actually been ground or machined to a smooth or low Ra surface, then shot peening will lead to a rougher surface area coating.

Everything about Pressure Washer Sandblaster

Coating, paints, as well as adhesives stick far better to a rough surface contrasted to a smooth surface area. An abrasive blasted surface area creates a support account with undercuts and more area for layers and also adhesives to grab onto. A sandblast roughed up surface area on a stainless handrail assists people get a much better hold also.

Rust and corrosion layers require to be eliminated also, particularly for safety layers satisfying the National Association of Corrosion Engineers (NACE) and Society of Surface Area Safety Covering (SSPC) standards. Three reasons to eliminate corrosion or deterioration with unpleasant blowing up are: Corrosion and also rust layers are weak and softer contrasted to the underlying steel.

Some Of Black Diamond Blasting Sand

A blast roughened surface supplies mechanical interlocking between the finishing and also substrate. No, since if a surface is as well harsh, then thinner protective coverings might not totally content cover the surface causing pinholes and corrosion of the underlying surface. Shot, grain, and abrasive blasting can reduce a few of the high heights in a surface area profile to boost rust protective coating performance.Clinical/ Dental Cleaning, coating prep work, etching, and my sources sprucing up of clinical gadgets and oral repairs. As an example, the investment or mold and mildew material on actors crowns or bridges can be delicately gotten rid of with a little benchtop sandblaster or micro-blaster. Hip, shoulder, oral as well as various other bone, and joint implants are blast cleansed to satisfy stringent FDA sanitation needs.

5 to 5 microns). Certain products such as lead-based paints and heavy steels create harmful or hazardous dirt when blown up. In these applications, specialized systems are needed to avoid the launch of harmful materials. Appropriate collection, handling, and also disposal of the media are called for. Wet or water blasting systems reduce the dirt issue.

Little Known Facts About Sand Blasting Sand.

Sandblasters or sandblasting operators can be injured throughout abrasive blasting. The high-pressure unpleasant stream can hurt skin and also eyes.Soft drink, completely dry ice, and wet blowing up keep components awesome throughout blasting. Abrasives and also blast media can obtain lodged right into gaps on a part and also can be tough to eliminate.

Validate the blasting process parameters with an additional examination or test. What are the consumable prices such as blast media, put on component replacements, and also system upkeep expenses? Exactly how several drivers are required to run the blast system?

Sandblasting Near Me Fundamentals Explained

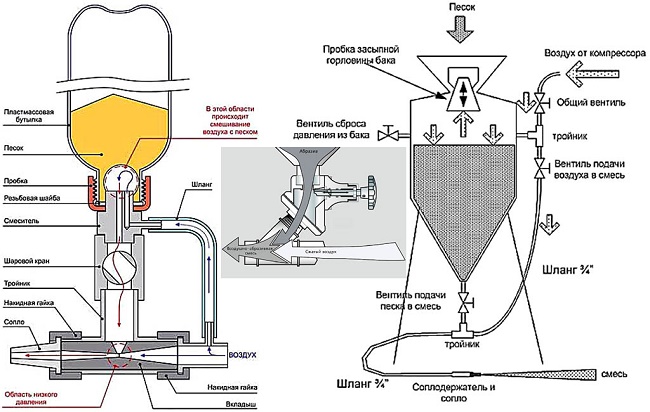

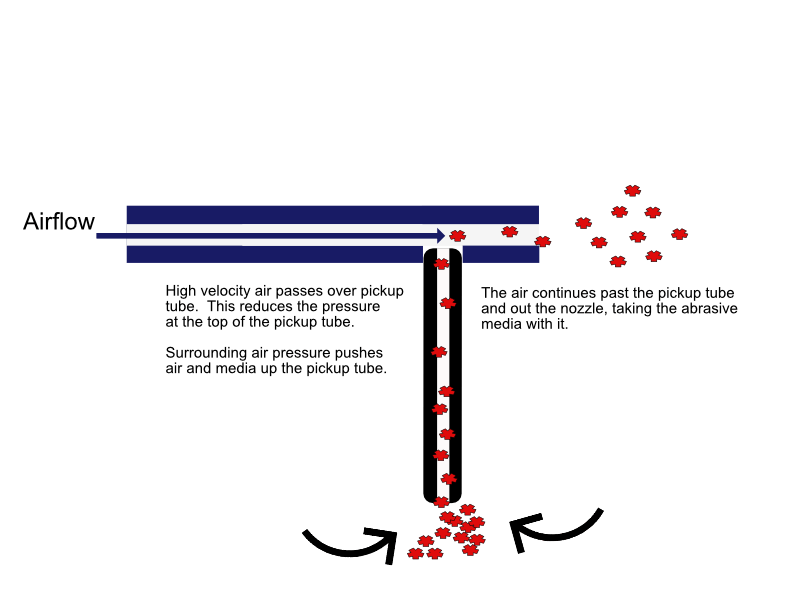

The first of the three types of sandblaster is the gravity-fed version. There are 3 standard parts to this design: an air compressor or pressurized air tank, a hand-held pressure gun with air hose pipe as well as a hopper on top of the gun. click this The tube attaches to the air storage tank, and the hopper is filled with silica sand.

They are composed of a big cylinder containing silica sand under high pressure. This is a little bit comparable to the concept behind an aerosol can.

Some Of Sand Blaster Harbor Freight

Report this wiki page